News Story

Engineering Students Fabricate Tomorrow’s Solutions Today

Inaugural Capstone Design Expo Highlights Real-World Innovations

How do we make medicine safer and more accessible for all? How do we design and build our infrastructure to be future-ready? What lessons can Earth learn from its moon? And as our planet heats up under the pressures of climate change, how do we keep cool? These are just a few of the pressing societal challenges facing the next generation of engineers and problem solvers — including the talented and hardworking students of the A. James Clark School of Engineering.

At the Clark School, we provide many exciting opportunities for our students to demonstrate leadership through experiential learning while creating solutions to some of our world’s greatest challenges. Among the opportunities for Clark School students, the year-long capstone courses that culminate in a design showcase are vital to training tomorrow’s engineers.

Our first annual Capstone Design Expo brings together more than 500 senior-level students from across Maryland Engineering’s civil and environmental, aerospace, mechanical, and bioengineering programs. Approximately 100 teams will showcase their capstone design projects, which will be judged by experts in their respective fields — with top team designs receiving cash prizes. One team will receive the overall Dean’s Award, presented by Samuel Graham, Jr., dean of the Clark School. “The Capstone Design Expo is a unique time to celebrate and a time for the community to learn about the great innovation happening in Maryland Engineering,” Graham said.

Early in the capstone design process, student teams are presented challenges from corporate partners, including event sponsor the Whiting-Turner Contracting Company. Working under the guidance of faculty members and industry experts, students engage in an engineering project process that helps them become career-ready. “We want our graduates to be prepared from day one,” said Graham. “What better way than to have our students team up with local industry and governmental agencies to address the problems that exist in the real world today?”

The Capstone Design Expo invites members of the Maryland Engineering community, along with friends and family to witness what Clark School seniors are doing to change the world. (For information on student teams and visitor registration visit the Capstone Design Expo site.)

What to expect at the Capstone Design Expo?

Teams of aerospace engineering students on the space track will present their innovative space system designs. Air track student teams from UMD’s Design Build Fly chapter and teams competing in Vertical Flight Society competitions will present their aircraft projects. New this year, a mixed team of space and air track seniors embarked on a hypersonics capstone co-taught by Igor Sikorsky Distinguished Professor in Rotorcraft James Baeder and Kevin Bowcutt ’82, M.S. ’84, Ph.D. ’86. A member of the National Academy of Engineering and a recognized expert in hypersonic aerodynamics, propulsion integration, and vehicle design, Bowcutt is senior technical fellow and chief scientist of Hypersonics for Boeing and provided collaboration from an industry perspective. The project’s prompt? To design a viable supersonic or hypersonic passenger transport jet.

The team is designing a supersonic vehicle that could fly at Mach 3.6 from Los Angeles to Tokyo within three hours instead of the 12 hours it takes on a conventional airliner. The project involves eight disciplines: configuration, aerodynamics, propulsion, thermal, structural design, mass properties, performance, and market and cost analysis. Team and propulsion lead Adin Goldberg has learned a lot over the course of the project — from the ins and outs of designing a jet propulsion engine to project management and communication skills. He’s excited to present the team’s poster and prototype: a toy-sized, 3-D-printed model. He hopes to test the model in the High-Speed Aerodynamics and Propulsion Laboratory before the competition. His big project takeaways?

The team is designing a supersonic vehicle that could fly at Mach 3.6 from Los Angeles to Tokyo within three hours instead of the 12 hours it takes on a conventional airliner. The project involves eight disciplines: configuration, aerodynamics, propulsion, thermal, structural design, mass properties, performance, and market and cost analysis. Team and propulsion lead Adin Goldberg has learned a lot over the course of the project — from the ins and outs of designing a jet propulsion engine to project management and communication skills. He’s excited to present the team’s poster and prototype: a toy-sized, 3-D-printed model. He hopes to test the model in the High-Speed Aerodynamics and Propulsion Laboratory before the competition. His big project takeaways?

“Even though it’s aircraft design — wing design, engine propulsion, and vehicle configuration — it’s still a lot of what we learned in our lower level classes, like iteration through equations and thermal analysis questions,” he said. “That makes some of these projects that sound unfeasible seem feasible with the numbers to back them up.”

Improving medical care:

Ethics, clinical trials, and entrepreneurship are just a few of the topics covered in the capstone design course for bioengineering and biocomputational engineering students. This year, 20 student teams used what they’ve learned to create their own engineering designs — from concept to product to business plan. Advised by Fischell Department of Bioengineering Lecturer Kyung Koh and working with Children’s National Health Center mentors, one team set out to create affordable and accessible telemedicine headphones tailored for diagnosing middle ear conditions in children ages zero to eight.

The engineering problem: hospital emergency rooms are overburdened with children suffering from ear infections, and testing equipment is expensive. Using a custom printed circuit board and designing their own casing and an interactive user interface, the team’s in-ear device would do the testing and send results to the parent or guardian through an app, while it sends raw data to the child’s doctor. The proposed telehealth solution has the potential to make ear health management more accessible, reduce unnecessary antibiotic use, and mitigate preventable hearing loss in children.

Team member Maya Wheeler, a graduating bioengineering senior on the public health policy track in the Federal Fellows Program at UMD, said the complicated hardware and software problem posed technical challenges. To meet them, the team got help from the Department of Electrical and Computer Engineering, the Maryland Robotics Center, and computer engineering junior Alfredo Santiago, whom Wheeler knew through her involvement in the Society for Hispanic Professional Engineers. While the team is still debugging code, Wheeler is proud of how far they’ve come. “Making this equipment easy to use and getting it down to $200 from more than $2,000 is a big deal,” she said. “This work makes medicine more accessible.”

Building adaptive devices:

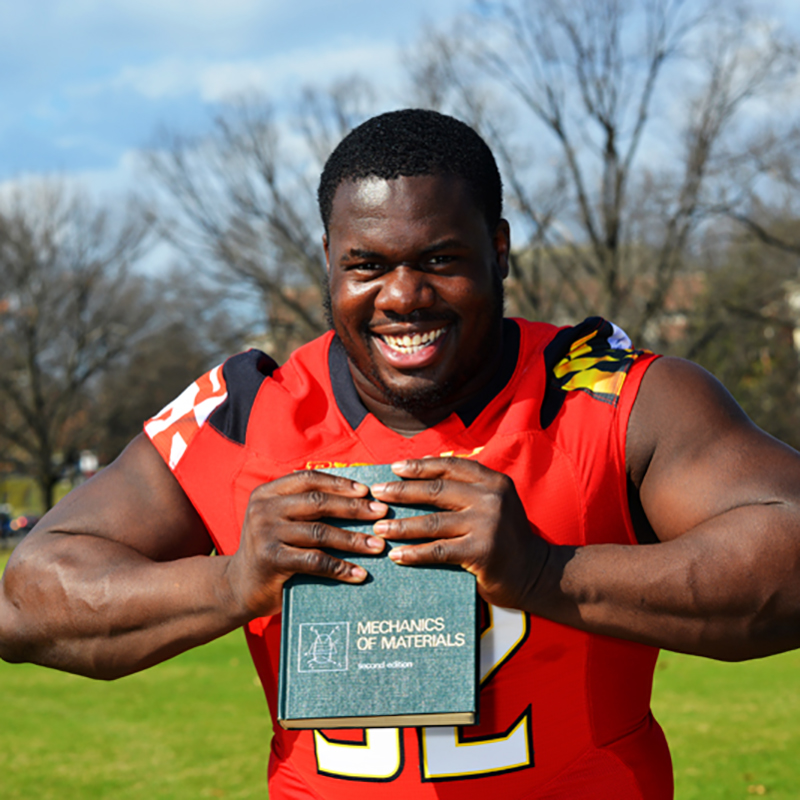

Mechanical engineering seniors highlight their talents and creativity in a capstone design course that challenges them to present project prototypes built to solve selected engineering problems. This year, two project teams presenting at the Capstone Design Expo are sponsored by Volunteers for Medical Engineering (VME), which provided each team a $350 spending budget to design and build assistive devices for Baltimore customers. Team 26 is working under guidance from Assistant Professor Davis McGregor on a bedside workstation. Team 9 is working under guidance from Assistant Clinical Professor Aris Cleanthous on a voice-activated treadmill for a little person.

The most special aspect of the capstone projects with VME is that students get to work on a “real and pressing problem for a real and specific customer, while having the support of an incredible organization,” Cleanthous said. “At the end of the semester, these teams get to deliver their creations to the customer who becomes the beneficiary of their hard work. You can't beat this kind of reward.”

Graduating mechanical engineering senior Owen Quinn is happy to see his team’s hard work pay off, from pen and paper design drafts to a functioning, physical project with possible future applications. “We are confident that our design is easily modifiable enough to be used as a basis for other treadmills, potentially helping other people who may need something similar,” he said.

Streamlining construction:

The capstone experience for civil and environmental engineering seniors emphasizes student creativity, design methodologies, evaluation of alternate solutions, feasibility considerations, and detailed system descriptions. Students build on skills acquired throughout their coursework and have hands-on experiences similar to those encountered by new engineers working in professional engineering and construction practice. This year, new Clark School corporate partner Allan Myers sponsored several student teams tackling problems posed by the civil contractor.

Working under the guidance of Professor Deb Niemeier, the Clark Distinguished Chair in Energy and Sustainability, and with Senior Project Manager at Allan Myers Will Sigafoose as client contact, one team aimed to solve the problems public agencies experience in the management of public construction projects. These commonly include schedule delays, cost overruns — and frustration. The proposed solution? A dedicated management team, or on-call group, responsible for internal and external communication, streamlining contract oversight, and enforcing clear roles, responsibilities, and deadlines for all parties of a conceptual Baltimore City project.

Graduating senior and team lead Justin Wu is a civil engineering major with a focus on transportation and project management. “This project is a good example of how to move public construction projects along more quickly and more efficiently,” he said. “We’re improving communication and coordination — factors that play a huge role in project schedule and cost.” Plus the project is “good preparation,” he said, for life after graduation, when he will go to work as a traffic design engineer at JMT.

Published April 26, 2024