Auto Shredder Residue for Renewable Construction Materials (Low Carbon Transportation Materials, LCTM initiative).

Principal Investigator

Goulias, Dimitrios G.

Sponsors

Joseph Smith & Sons Inc

https://smithindustriesgroup.com/

https://cee.umd.edu/news/story/goulias-tapped-to-develop-renewable-construction-materials

https://today.umd.edu/briefs/engineer-awarded-735k-to-develop-renewable-construction-materials-from-auto-waste?utm_source=Publicate&utm_medium=email&utm_content=...&utm_campaign=Final+20241018EMAIL

https://eng.umd.edu/news/story/goulias-tapped-to-develop-renewable-construction-materials

Evaluating Correlation Between Slip Resistance and Skid Resistance of Pavement Markings at Crosswalks

Principal Investigator

Goulias, Dimitrios G.

Sponsors

Maryland State Highway Authority (MSHA)

Federal Highway Administration (FHWA)

Performance of Ultra Thin Bonded Wearing Course (UTBWC) During Winter Snow Ice Events

Principal Investigator

Goulias, Dimitrios G.

Sponsors

Maryland State Highway Authority (MSHA)

Federal Highway Administration (FHWA)

Evaluating Maryland Asphalt Mixtures Using Balanced Mix Design for Durable Pavements

Principal Investigator

Goulias, Dimitrios G.

Sponsors

Maryland State Highway Authority (MSHA)

Federal Highway Administration (FHWA)

Data Mining in Transportation Geomaterials & Infrastructure Health Monitoring Through Machine Learning

Principal Investigator

Goulias, Dimitrios G.

Sponsors

Maryland Transportation Institute (USDOT)

https://cee.umd.edu/news/story/monitoring-bridge-wear-and-tearmdashwith-radar

Implementation of Ground Penetrating Radar for Condition Assessment & Monitoring of Critical Infrastructure Components of Bridges & Highways Phase I to Phase III

Principal Investigator

Goulias, Dimitrios G.

Sponsors

Maryland State Highway Authority (MSHA)

Federal Highway Administration (FHWA)

Development of a Manual using Non-Destructive Testing (NDT) & Case Studies on Precast Concrete Elements in Highway Construction

Principal Investigator(s)

Goulias, Dimitrios G.

Sponsors

Federal Highway Administration

Objective of this project is to develop a guidance manual for State Highway Agencies (SHA) for non-structural precast concrete elements for highway construction. The manual will provide effective uses for different types of non-destructive testing and inspection. Furthermore, it is the objective of the project to document three case studies of SHAs non-structural precast concrete elements acceptance programs. The case studies shall allow SHAs to utilize guidance for developing effective acceptance programs. Thus, the specific objectives are: (i) develop recommended procedures for nondestructive testing (NDT) of completed precast concrete elements; and (ii) document three case histories of acceptable and reasonable acceptance programs.

UPV and GPR–NDT Testing at Precast Concrete Elements

Effective Implementation of Ground Penetrating Radar (GPR) for Condition Assessment & Monitoring of Critical Infrastructure Components of Bridges and Highways

Principal Investigator(s)

Goulias, Dimitrios G.

Sponsors

Maryland State Highway Authority (MSHA)

Federal Highway Administration (FHWA)

The objective of this study is to assist State Highway Administration (SHA) engineers, technicians, and decision makers in their current effort to explore the use of Ground Penetrating Radar (GPR) in assessing the condition of critical infrastructure components and to identify potential improvements in GPR data analysis. With regard to pavement structures, a new methodology is suggested to improve the accuracy of GPR data analysis. The initial analysis and results indicate that this new method, Multi-scale Pavement GPR data Analysis (MPGA), has the potential to add value and accuracy to pavement thickness data used in pavement management and rehabilitation analysis. For bridge deck evaluation, the need to capture moisture effects and detailed depth information are imperative. The use of advanced GPR data analysis techniques such as migration imaging (for concrete cover depth measurement applications among others), Fourier analysis of GPR waveforms (for qualitative bridge deck moisture analysis) and emerging techniques such as Short Time Fourier Transform analysis (for anticipated quantitative moisture analysis) are suggested. Current quality control (QC) on precast concrete elements is based on plant inspections and periodic audits that have important limitations. Specifically, current precast quality assurance practices include labor intensive activities and sporadic inspections with the potential to miss important problems. This study examines how GPR can be used to address several of the inspection applications needed in precast concrete production, including an evaluation of concrete cover depth, reinforcement location and section thickness. The work under this multiyear project was undertaken in cooperation with ADOJAM and Starodub Inc.

GPR Pavement Thickness Evaluation using MPGA Analysis (US15)

Bridge Deck GPR Evaluation with Migration Analysis—Deterioration & Moisture Effects (Route 290)

GPR Data Analysis of a Precast Concrete Wall Panel: Integrated 2 to 3 Inch Depth

Note: Plan View Migrated Results (Hot/Red Color Map); Individual Alpha Numeric Scans (Gray Color Map)

High Performance Concrete Pavements

Principal Investigator(s)

Goulias, Dimitrios G.

Schwartz, Charles W.

Sponsors

Maryland State Highway Authority (MSHA)

Federal Highway Administration (FHWA)

The objective of the study was to examine the benefits of using innovative pavement concrete mixtures for enhancing the flexural fatigue resistance and improving the shrinkage behavior of concrete pavement mixtures. The study was sponsored by Federal Highway Administration (FHWA) under "Test and Evaluation Project 30" (TE-30), "High Performance Concrete Pavement" (HPCP) and by the Maryland State Highway Authority (MSHA). In addition, the concrete industry is actively involved in this significant and innovative effort.

The study included extensive laboratory evaluation of several experimental fiber reinforced concrete and low shrinkage mixtures. Selected concrete mixtures from the laboratory study were used in the construction of test sections in the Salisbury bypass on US-50 for evaluating their performance under in-service loading and environmental conditions. Pavement instrumentation was also installed and includes: concrete strain gages for measuring slab surface stains under traffic loadings; linear variable displacement transducers (LVDTs) to measure concrete slab deflections under traffic; thermocouples to measure concrete slab temperature profile; vibrating wire gages to measure long term strains in the concrete slabs; and Whitmore plugs to measure changes in joint width. The constructed instrumented experimental pavement sections are currently undergoing load testing. Profile measurements of diurnal (temperature curling) and seasonal (moisture warping) slab changes are also included as part of the field monitoring program. The analytical portion of the study included finite element analysis (FEM) for both pre-construction predictions of expected pavement response and post construction monitoring of the experimental concrete slabs. Particular emphasis is placed on comparisons of stiffness degradation rates between the fatigue test section and the control section and on differences in temperature curling and moisture warping between the shrinkage test section and the control section.

Field Instrumentation at US-50

Paving US-50 with experimental Fiber Reinforced Concrete

Increasing Durability of Hot Mix Asphalt Pavements Designed with the Superpave System

Principal Investigator(s)

Goulias, Dimitrios G.

Schwartz, Charles W.

Sponsors

Maryland State Highway Administration

Federal Highway Administration

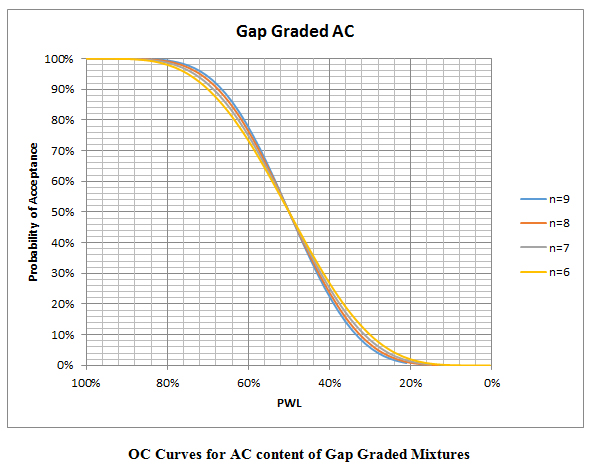

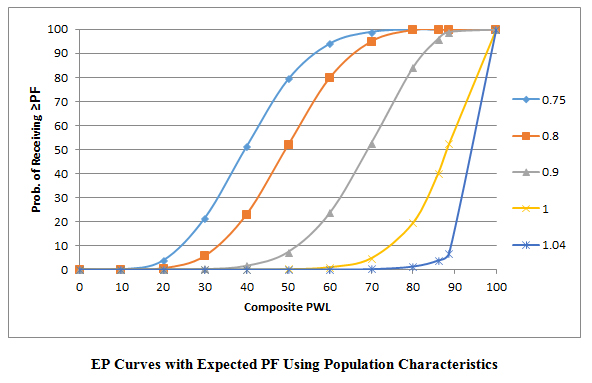

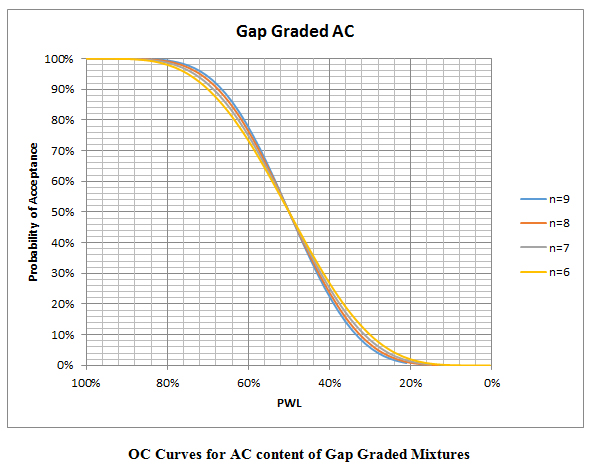

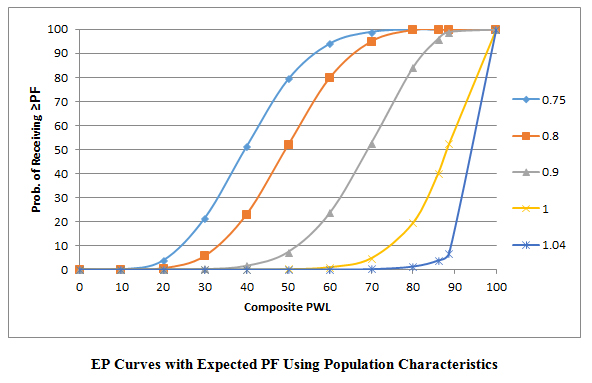

State Highway Administration (SHA) concerns with the lower asphalt levels in HMA mixes have lead efforts to explore strategies to increase the asphalt content in Superpave mixes. National studies identified methods for adjusting binder content without compromising rutting performance of asphalt mixtures and remaining loyal to the Superpave philosophy. The applicability of these methods to Maryland SHA conditions were addressed based on the findings of recent National Cooperative Highway Research Program projects, ongoing discussions with SHA engineers, and experts’ feedback in this area. Furthermore, this study addressed the differences in HMA properties that have been observed over the years between samples taken at the plant versus behind the paver. A large set of SHA QA and QC data was analyzed statistically in the context of current specifications and pay factors to evaluate potential risks to both SHA and contractors. The research team developed the Operating Characteristic (OC) curves based on the QA data and for estimating the risks to SHA and contractors (Type I and II risks). With the aid of a new simulation tool the associated pay factors (PF) and expected pay (EP) were analyzed using the population characteristics and considering potential correlations between the HMA mix parameters.

Material Quality Assurance Risk Assessment

Principal Investigator(s)

Goulias, Dimitrios G.

Sponsors

Maryland State Highway Administration

Federal Highway Administration

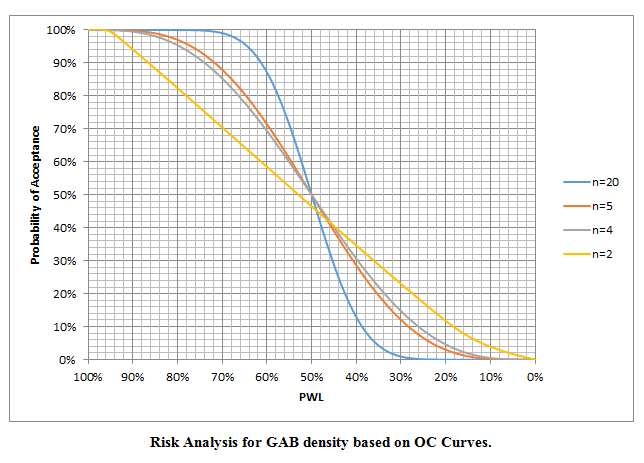

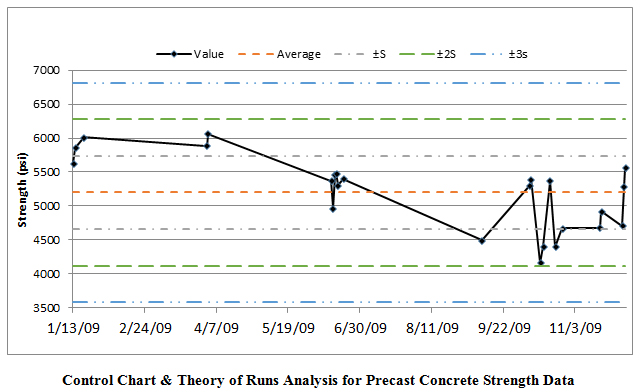

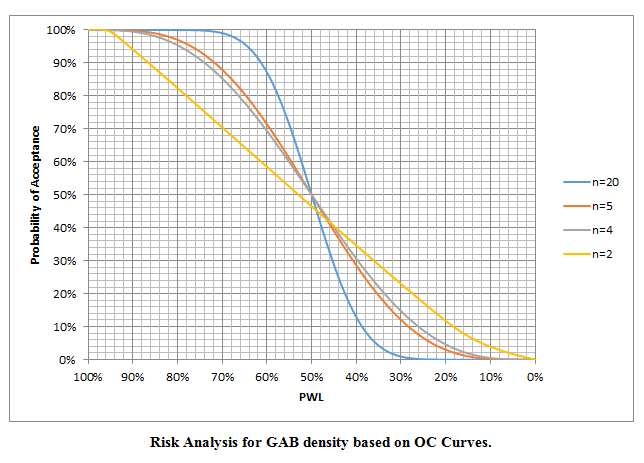

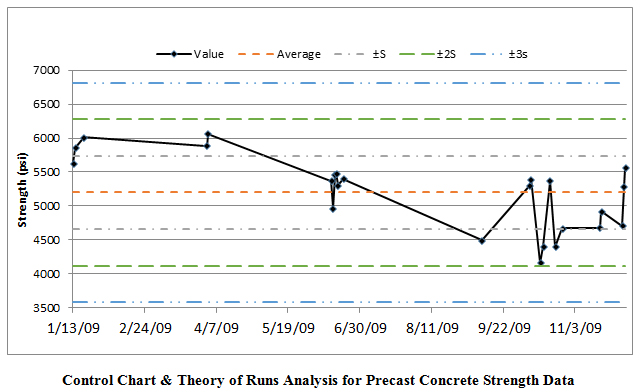

Objective of this study is to assess current quality control and quality assurance, QC/QA, procedures for a variety of highway materials, (including graded aggregate bases, GAB, precast concrete for drainage structures, structural steel, rebars, coatings, and neoprene strip seals), in regards to: a) conformance in relation to the federal requirements CFR 637 – Title 23 for defining QA plans, Independent Assurance (IA) procedures, and material certification; b) identify potential improvements to existing SHA QA plans; c) assess product variability based on production QC data; and, d) quantify risks related to material acceptance data with Operating Characteristics (OC) Curves.

Click the below thumbnail images to view each graph.

New Technology-Based Approach to Advance Higher Volume Fly Ash Concrete with Acceptable Performance

Principal Investigator(s)

Goulias, Dimitrios G.

Sponsors

U.S. Department of Energy, Combustion Byproducts Recycling Consortium (CBRC)

This research project is undertaken with the National Ready Mix Concrete Association (NRMCA) and concrete experts in maturity. It suggests novel science-based approaches to address the slower rate of strength gain and delayed setting times of HVFA concrete. This project will address the two major stumbling blocks, lower early-age strengths (less than 7 days) and delayed initial setting times, which prevent the large scale utilization of HVFA concrete. Objectives of the project are: to demonstrate by using a maturity based approach that HVFA concrete in the structure has sufficient early-age strengths to allow for optimized construction scheduling; and to demonstrate that by using some suitable chemical admixtures or additions the initial setting times of Class C fly ash concrete is not delayed. Based on these approaches a step by step procedure will be developed that the concrete producer and the construction team can adopt to manage the resulting properties of HVFA concrete during mixture development and construction scheduling. The project includes extensive filed and laboratory testing with instrumentation related to the maturity concept of concrete, and non destructive testing of concrete using the pull out method.

Preparation of Instrumented Concrete Blocks with pullout inserts and I-buttons for Maturity testing

Sure Cure System and Concrete Cylinders

Recycled Material Availability in Maryland

Principal Investigator(s)

Goulias, Dimitrios G.

Aydilek, Ahmet H.

Sponsors

Maryland State Highway Authority (MSHA)

Federal Highway Administration (FHWA)

Currently the use of recycled materials in highway applications is limited due to regulatory, environmental, and technical restrictions on their potential use. The lack of performance information when these recycled materials are used in highway applications is also a major stumbling block. It is the objective of this research to (i) identify such constraints and propose methods to reduce or eliminate those restrictions, (ii) document the state of the art practice on the use of the selected recycled materials, (iii) review the known performance of each listed recycled material based on past experience, and (iv) develop the technical requirements for their safe use in alternative applications of highway projects for Maryland conditions.

Crushed Returned Concrete Aggregate (CCA)

Design and Evaluation of Foamed Asphalt Base Materials

Principal Investigators

Schwartz, Charles.

Goulias, Dimitrios G.

Sponsors

Maryland State Highway Authority (MSHA)

Federal Highway Administration (FHWA)

Establish Correlation between Aggregate Properties and Pavement Friction

Principal Investigator

Goulias, Dimitrios G.

Sponsors

Maryland State Highway Authority (MSHA)

Federal Highway Administration (FHWA)

Catalog of Material Properties for Mechanistic-Empirical Pavement Design

Principal Investigators

Schwartz, Charles.

Goulias, Dimitrios G.

Sponsors

Maryland State Highway Authority (MSHA)

Federal Highway Administration (FHWA)

Passive Wireless Concrete Maturity Monitor

Principal Investigator

Goulias, Dimitrios G.

Sponsors

Maryland Industrial Partnership Program, (MIPS)

Evaluation of Aggregate for Masonry Mortar: Aggregate Characteristics & Impact on Mortar Properties: ICAR

Principal Investigator

Goulias, Dimitrios G.

Sponsors

National Stone, Sand and Gravel Association, (NSSGA).

Technical Support for Ride Quality Specification

Principal Investigators

Schwartz, Charles.

Goulias, Dimitrios G.

Sponsors

Maryland State Highway Authority (MSHA)

Federal Highway Administration (FHWA)

High Performance Portland Cement Concrete for Airfield Pavements

Principal Investigator

Goulias, Dimitrios G.

Sponsors

Minta Martin Grant Award